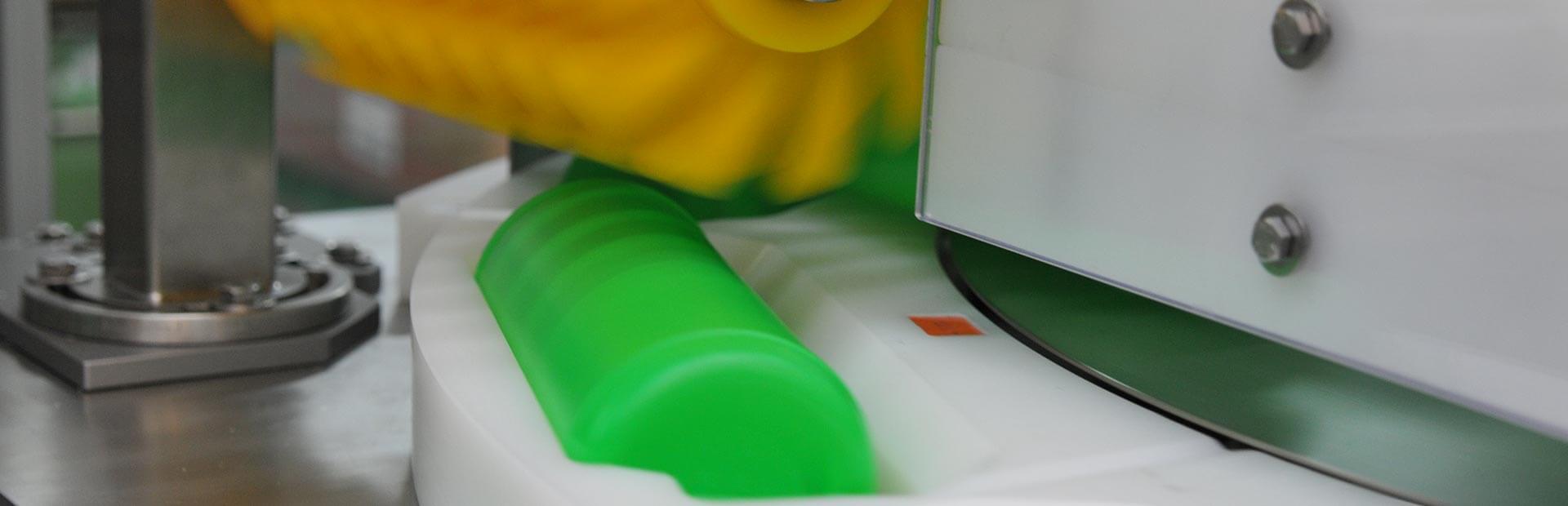

Sorter

read more

dmp centrifugal sorters for separating, orientating and feeding of closures (e.g. jars, lids, caps, pumps etc.) and other small parts.

The size (ZSH-350 up to ZSH-1500) of the dmp sorter depends on shape and size of the parts to be sorted and on the requested output (40 up to 450 pcs/min).

Due to the integrated storage and feeding unit dmp sorters have a very compact size. The volume of the storage bin is adjusted to the requested output and allows a continuous, undisturbed machine run with reduced refilling intervals.

Storage, feeding unit and sorter can be delivered separately – on request.

The especially careful treatment of the articles by the centrifugal sorter allows the sorting of products with scratch-sensitive surfaces. The quick and easy format change without tools enables a fast changeover to various products (e.g. caps/pumps) so that also the sorting of small number of pieces becomes profitable.

Bottle unscrambler

read more

dmp bottle unscramblers for separating and positioning of bottles and bigger containers. These are fed, correctly positioned to further production processes (filling, printing, labeling, etc.). The following types of dmp unscramblers are available:

ZSKF

Bottle unscramble type ZSKF for positioning of small containers (5ml up to 100ml, max. H200mm). Depending on machine size (ZSKF-820 up to ZSKF-1500) and on shape and size of bottles. This unscrambler has an output of up to 300 pcs/min.

ZSF

For positioning of bottles and containers (100ml up to 2l) the dmp unscramble type ZSF is applied. Depending on size (ZSF-820 up to ZSF-2000) and products to be sorted, the unscrambler has an output of up to 400 pcs/min.

The dmp bottle unscramblers are also available for inserting bottles into pucks (type BE). Pucks are occupied by 100%, when being fed to further manufacturing processes.

Storage bin and feeding unit are integrated and can be adapted to customers´ requirements. This allows a compact construction.

Feeding technique

read more

Storage

dmp manufactures hoppers and storage bins in different sizes due to individual requirements. Size and design result from existing conditions. Combined with elevators resp. parallel belt conveyors it is possible to overcome different floors (e.g. storage on the second floor and sorter on the first floor).

Orientator

For orientation of closures with recessed grip, dosing pumps, bottles etc.

dmp orientators can be supplied as linear or rotary unit. The orientator can be integrated in existing machines (e.g. unscrambler, sorter, capper) or it can be placed separately.

The detecting can be done mechanically or by camera technique. The orientation is made pneumatically by turning cylinder or by servo motor. Orientation of bottles standing in pucks is also possible.

Pucks

Pucks manufactured by dmp can handle upside-down or not stable containers. They also reduce times for format changes at packing lines, as the conveyors need not to be adjusted - only pucks have to be changed.

Conveyor systems

The dmp delivery program includes separate conveyors as well as complete conveyor systems for various applications. Conveyors are available in different lengths (from 200mm up to…..) and widths (45 up to 600mm).

Air cleaning and suction units

Air cleaning and suction units from dmp for removal of dust and dirt particles out of jars, bottles and other containers. These units are available as separate (and mobile) or as integrated solution.

Filling Machine

read more

Filling machines are available as linear or rotary construction with different dosing systems. It is possible to fill pasty-like or liquid products. In the field of filling technique dmp cooperates with well-known manufactures of the packaging industry and they also develop their own filling techniques so that complete packaging lines can be supplied from one source.

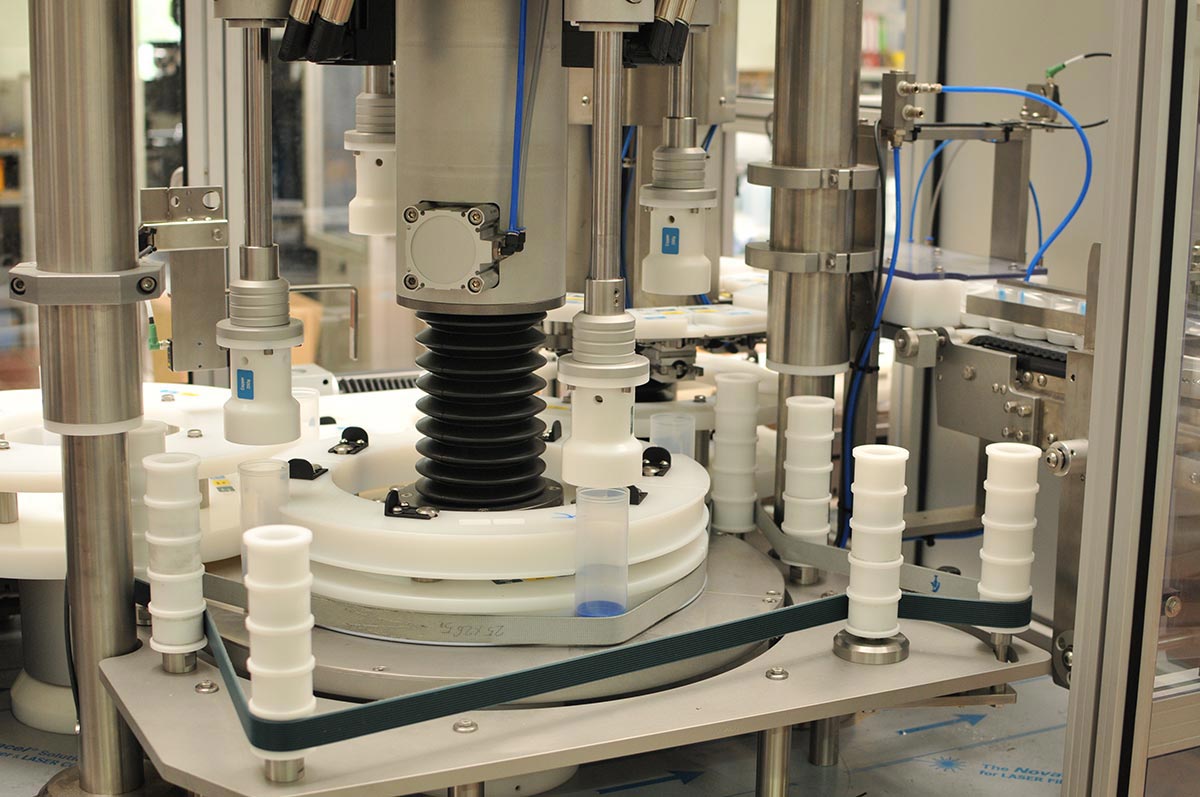

Capping Machine

read more

The single-acting dmp capper is used e.g. for screwing of caps or lids, whereas the combined capper is used e.g. for pressing-on plugs and subsequent screwing of caps.

Depending on line output dmp cappers are available as linear or as rotary construction. Because of its easy handling the small quantity of change parts and short changeover times the dmp linear capper is ideal for smaller production units and line efficiency <80pcs./min.

For a line efficiency >80pcs./min the dmp rotary capper is applied.

The integrated servo technique is responsible for the angle screwing of caps and finishes the screwing by torque.

Furthermore an orientation during the screwing process is possible so that a separate orientation unit is not necessary.

A control and discharge device for ejecting faulty or not screwed containers can be integrated in the capper.

Format changes are made without tools.

Assembling Machine

read more

dmp assembling machines for assembling of pre-fabricated products or separate components , e.g. closures (two or more pieces), inserting of wads, assembling of deo sticks etc. The output (40 up to 250 pcs/min) depends on size and products to be assembled.

The assembling machines can be delivered as linear or rotary construction.

Final control, control of label or bar code can be integrated. The assembling machines are available as single-acting or as combined machine.

The assembly can also be done by robotic automation.

Depucker/Converter

read more

Parallel belt conveyor

The dmp parallel belt conveyor (type PGH) lifts the filled and screwed containers out of the pucks, output up to 300 pcs/min. The containers are fed to further manufacturing processes, e.g. labeling cartooning etc. The pucks are fed by the conveyor system back to e.g. the bottle unscrambler.

Depucker

The compact, robot controlled depucker (type USE) is also used for lifting containers out of pucks but at the same time it allows the converting of containers (e.g. turning by 180°, placing onto conveyors with different height or displaced by 90°). An output of up to 120 pcs/min is possible.

The dmp converter is also available as rotary construction which allows a line efficiency of up to 400 pcs./min.

Depalletizing/Palletizing

Modular and Mobile Palletizing Cabin

read more

In the range of depalletizing/palletizing we cooperate with our business partner Kawasaki Robotics GmbH.

The modular and mobile palletizing cabin is characterized by an innovative conception. Together with a space-saving robot from Kawasaki it enables an extremely compact construction. By this the dmp palletizer is ideal for installation into existing lines.

Due to the modular construction the palletizing cabin can be extended in any way in future, so that it stays flexible also when requirements change.

By software adjustment individual configurations and modification wishes can easily be realized without any complications at any time.

As the dmp cabin is mobile, there are logistic advantages. Long installation times are eliminated and efficient changeable applications are possible.

Thus modern robot technique becomes cost-effective also for smaller coompanies